In-Mould Labelling (IML) is an advanced technique that fuses printed labels with injection-molded plastic, creating a seamless, durable and premium-quality finish. The entire process relies on precision engineering, robotics and high-end automation to ensure consistency, strength and visual appeal. Below is the complete workflow of our IML process:

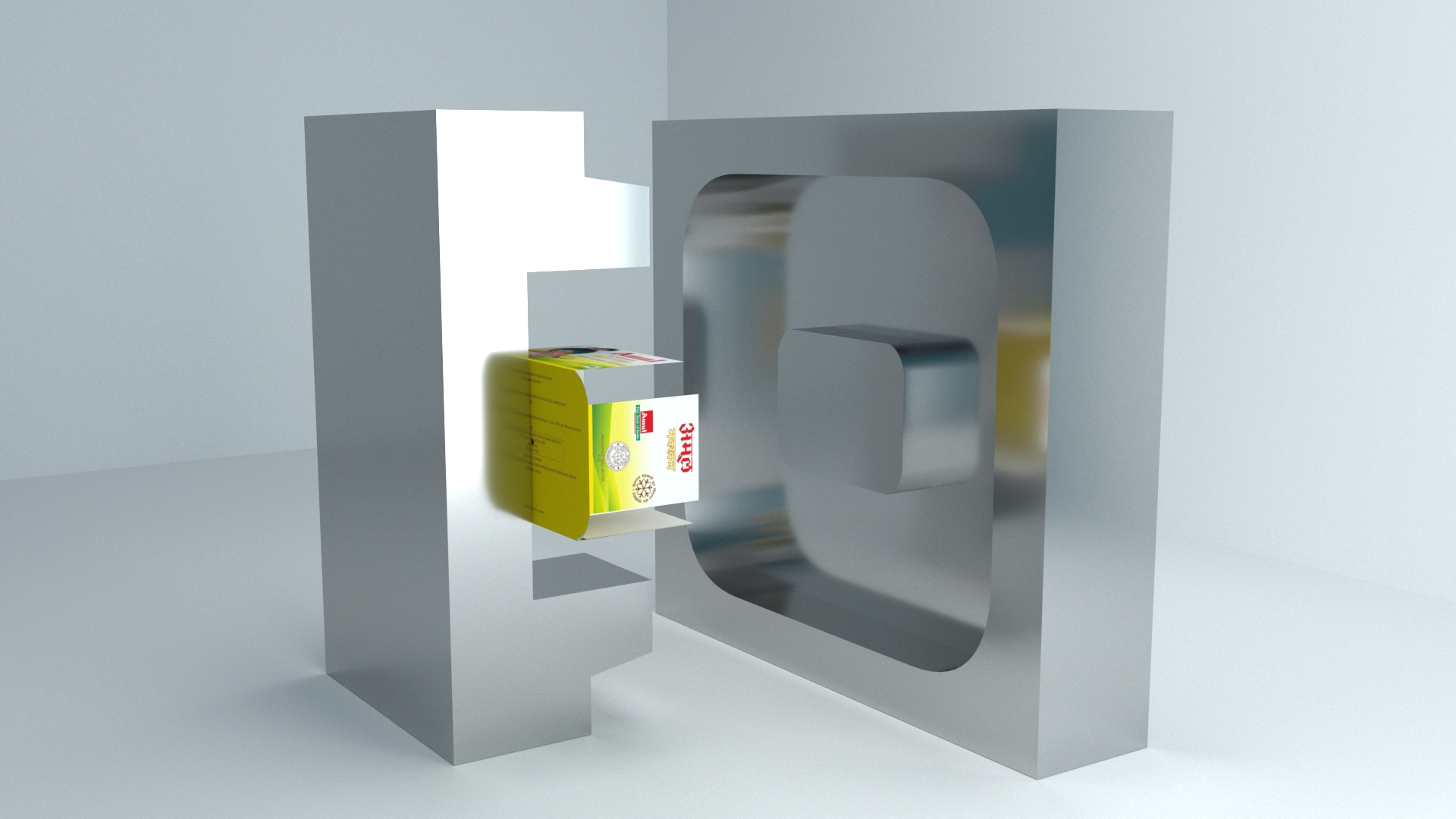

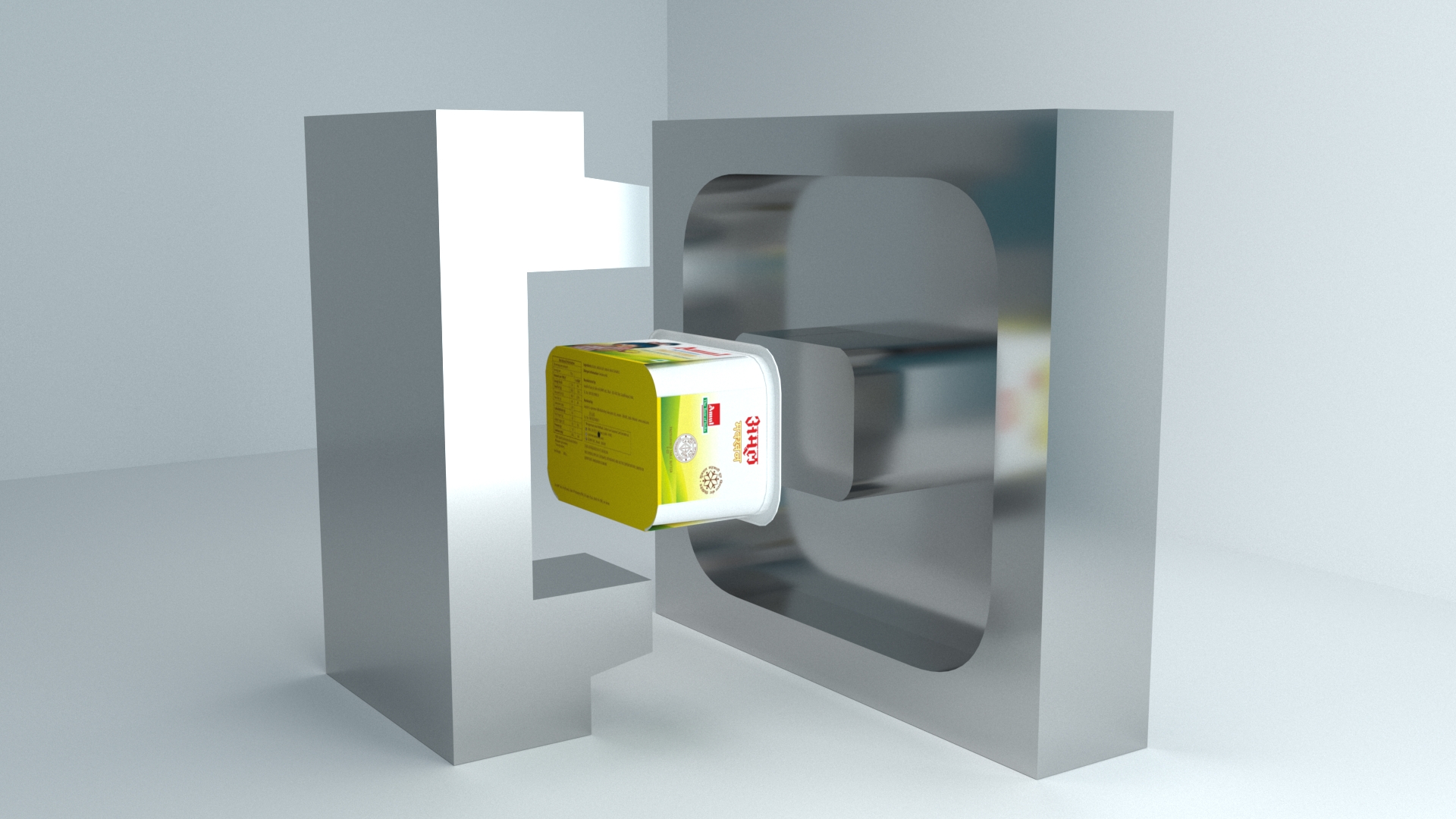

Molten polymer (PP/PE) is injected into the mould, where heat and pressure permanently bond the label to the product surface.

Molten polymer (PP/PE) is injected into the mould, where heat and pressure permanently bond the label to the product surface.

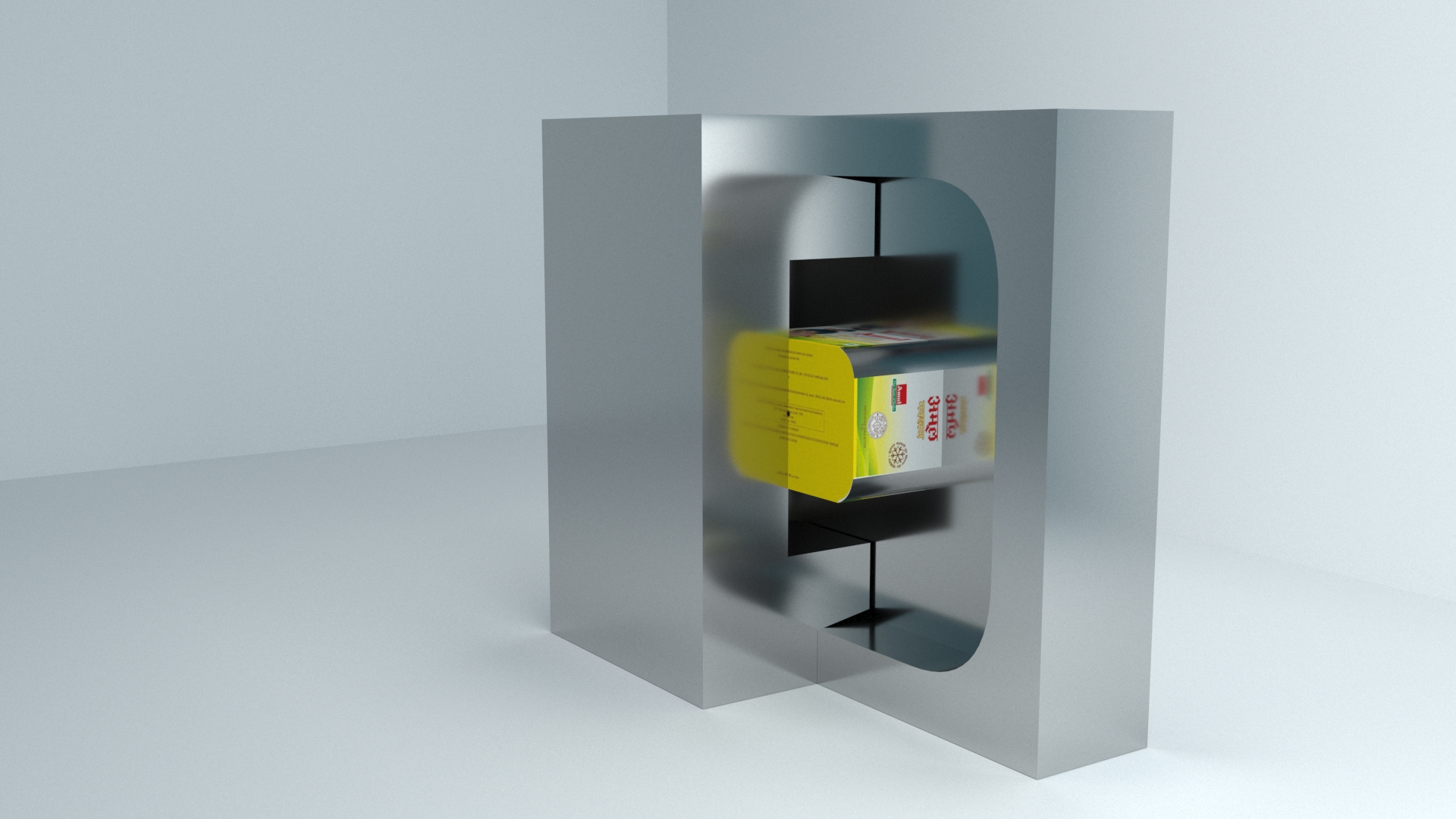

After cooling, the mould opens and ejector pins release a perfectly integrated, ready-to-use product.

Vision systems check label adhesion, alignment and print accuracy. Any deviations are isolated for review.

Verified units are packed using automated systems—shrink wrap, vacuum sealing or protective trays for maximum safety.

Each batch is documented, sealed and delivered through reliable logistics partners with full traceability.

We offer recyclable, biodegradable, and reusable packaging materials designed to reduce environmental impact while maintaining strength, durability, and premium aesthetics.